Manufacturing Excellence

State-of-the-art facilities and processes

Our Manufacturing Process

From concept to completion, our comprehensive process ensures quality at every step

Initial Consultation & Design

We work closely with clients to understand their requirements and develop detailed specifications. Our engineering team creates precise 3D models and simulations to optimize the casting design.

Pattern Making & Mold Preparation

High-precision patterns are created based on the approved designs. These patterns are used to form molds with exacting specifications, ensuring dimensional accuracy in the final castings.

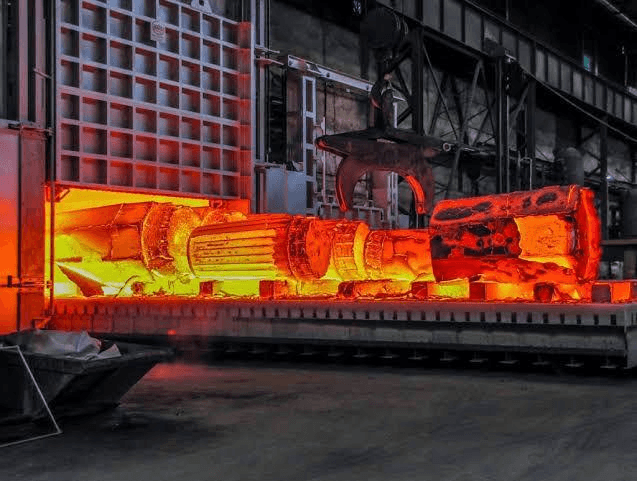

Melting & Pouring

Raw materials undergo rigorous quality checks before melting. Our advanced furnaces achieve precise temperature control and chemical composition, verified by spectrometer analysis before pouring.

Heat Treatment & Finishing

Castings undergo specialized heat treatment processes to achieve desired mechanical properties. Final finishing operations include shot blasting, machining, and surface treatments as required.

Quality Assurance & Delivery

Comprehensive testing including dimensional inspection, microstructure analysis, and mechanical property verification ensures every casting meets specifications before careful packaging and delivery.

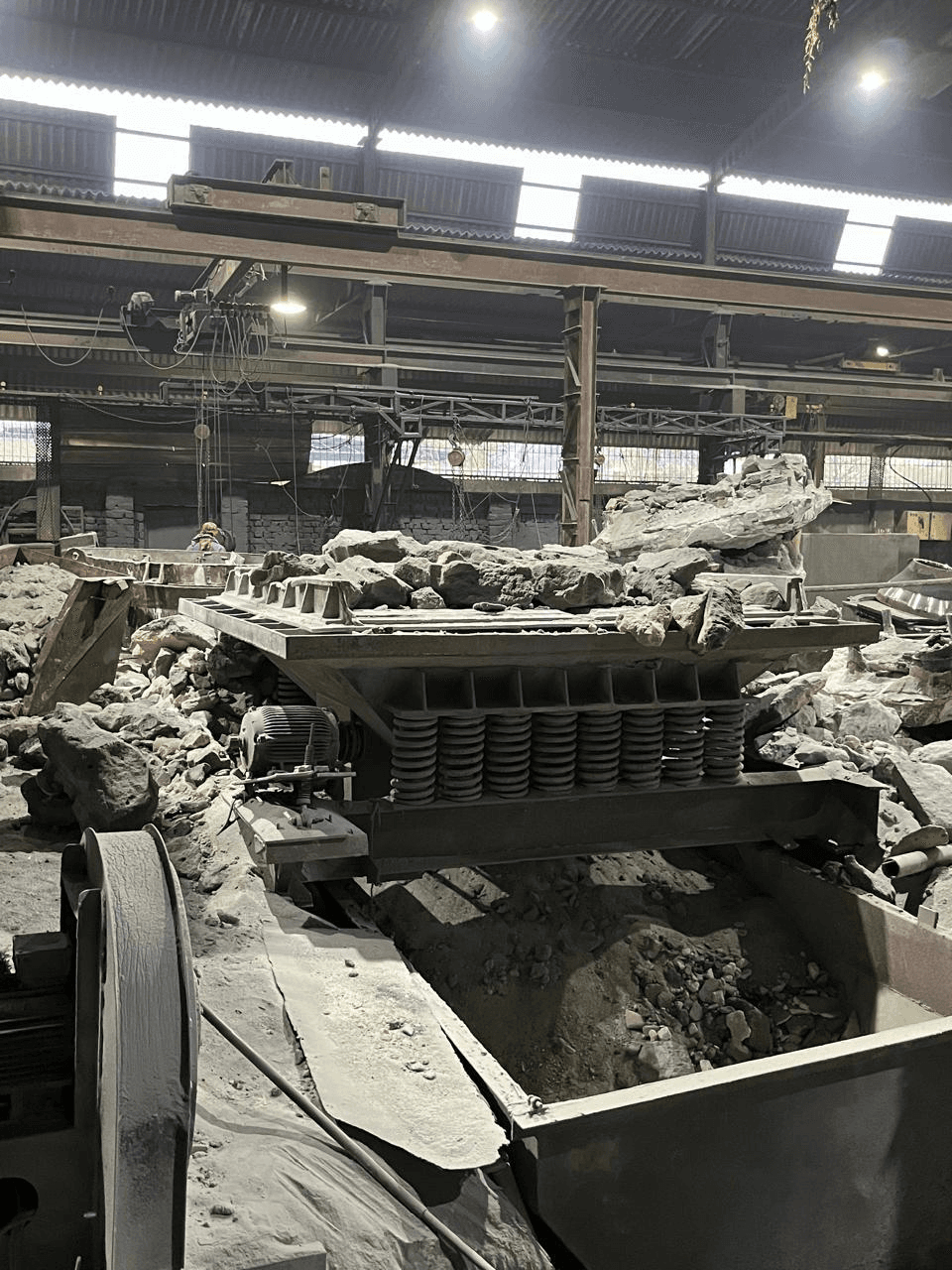

Mould & Core Preparation

Advanced sand mixing and preparation with CO₂ process

Melting & Pouring

Precision mould making with quality sand and expert craftsmanship

Knockout

Specialized core making for complex internal geometries

Heat Treatment

Precise cutting of risers and runners followed by quality finishing

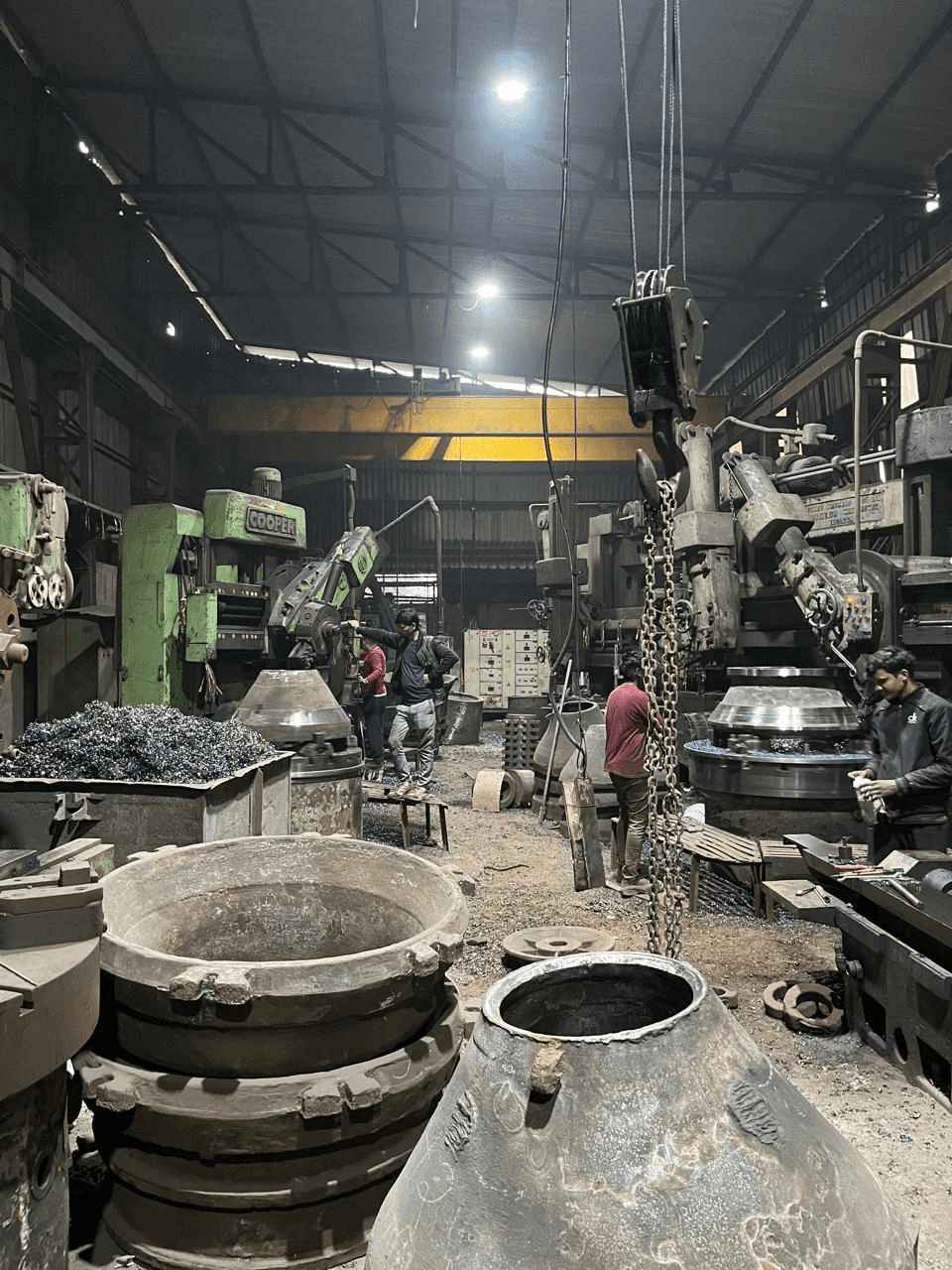

Grinding & Fettling

Environmental-friendly sand recycling and processing

Machining

Rigorous quality control and dimensional verification

Technical Capabilities

melting Equipment

- 1650KVA Induction melting Panel (Inductotherm Make)

- 3 Crucibles (4000Kg, 3000Kg, 1000Kg capacity)

- Laddles of various capacities (250Kg to 4000Kg)

- Laddle heating Systems

- Liquid Metal temperature indicators (Immersion type)

- Bailing machine for scrap handling

moulding Equipment

- Complete CO₂ sand reclamation and handling system

- Super mixer for CO₂ moulding sand with storage hoppers & silos

- Normal sand Muller semi automatic with screw feeding system

- Compaction tables for Semi automated moulding

- CO₂ storage tank with pressure regulation system

- Complete tools for sweep moulding

- All shape and size mould boxes

- Paint mixture machine for homogenizing

infrastructure Equipment

- 1600KVA H.T. Power Connection from DHBVN

- Backup D.G sets (380 KVA and 180 KVA)

- In-house chemical analysis Laboratory

- Dedicated tube well water supply

- 4000 Sq. mtrs. facility on Gurgaon-Alwar Road

- Office Block and Working Shed

- Pattern Shop & Machine Shop

- Transformer Room & Generator Room

heatTreatment Equipment

- 02 Oil Fired furnaces for annealing, normalizing and water quenching

- Large furnace (100'x100'x50') with 05 Thermocouples

- Medium furnace (80'x100'x50') with 04 Thermocouples

- PDI controlled auto cut off heating system

- Online temperature recorder connected to main server

- 5 M.T. fork lift crane with 20'X10'X8' quenching tank

- Air purging and water replenishing system

grindingSection Equipment

- Shot Blasting machine (48' table size)

- 06 Swing Grinders

- 08 Straight Hand Grinders

- 04 Pencil Flexible Grinders

- 04 Surface polishing angle grinders

- Electronic Weigh Bridge (5.0 MT)

- Crane Hanging suspended electronic scale (5 M.T.)

- 04 ARC Welding Sets

- MIG Welding unit

- O2 Manifold system

- 10 LPG Cylinders (19 kg)

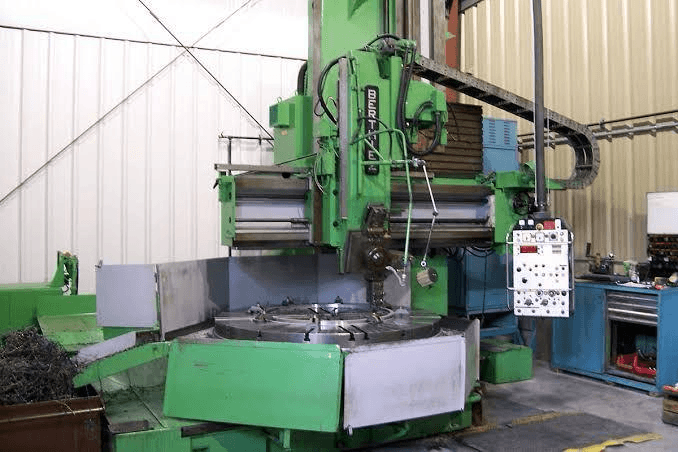

machineShop Equipment

- 07 Vertical Turning Lathe Machines (various capacities)

- Double Head Plano miller with Double Bed

- Lathe Machines (20' and 12' Center Height)

- 100 Tonnage Hydraulic Press

- Tool Grinder

- Marking Table (6'x3')

- Bench Type Surface Grinder

Manufacturing Capabilities

State-of-the-art machinery and testing facilities

Machining Center

| Machine | Capacity | Qty |

|---|---|---|

| VTL Machine | 2000x2200x1200 | 01 |

| VTL Machine | 1800x2000x1500 | 02 |

| VTL Machine | 1600x1600x1200 | 01 |

| VTL Machine | 1400x1400x1000 | 02 |

| VTL Machine | 1050x1150x1000 | 01 |

| Double Head Plano Miller | 8000x3000 | 01 |

| Lathe Machine | 20” Center Height | 01 |

| Lathe Machine | 12” Center Height | 01 |

| Drill Machine | - | 01 |

| MNTR Milling Machine | - | 02 |

| Hydraulic Press Machine | 100 Ton | 01 |

Testing Facilities

Chemical: 22-channel Spectrometer

Advanced chemical composition analysis

Physical: Rockwell & Poldy Hardness Testing

Comprehensive material strength analysis

NonDestructive: Ultrasonic, MPT

Advanced flaw detection and quality assurance

Pattern Making

woodworking

Bend saw, Hex saw, Drill machine

storage

12 Racks with sliding rollers, 3MT crane

Heat Treatment

furnaces

2 Oil-fired (100'x100'x50' & 80'x100'x50')

controls

PDI controlled, Online temperature recording

quenching

20'x10'x8' tank with air purging system

Infrastructure & Support Facilities

Comprehensive infrastructure supporting our manufacturing excellence

power Supply

- 1600KVA H.T. Power Connection

- 04 Air Compressors with surge tank (10 HP & 15 HP Load)

- Backup D.G sets (380 KVA and 180 KVA)

material Handling

- 10 EOT cranes (2.5 to 15 tonne capacity)

- Electronic and manual weighment scales

- Fork lift crane (5 M.T. capacity)

pattern Shop

- Bend saw

- Flat Hex saw wood cutting machine

- Wooden drill machine

- 12 Rack system with sliding rollers

- 3 M.T. Crane for pattern handling

- Complete pattern repair tooling

office

- Fully furnished office block

- Complete computerization with ERP systems

- Design division with 2D AutoCAD

- SolidWorks for 3D modeling

- Dedicated technical documentation center

Raw Materials & Resources

We maintain strict quality control over our raw materials, sourcing only the finest quality inputs for our casting process.

Primary Materials

Steel Scrap is our main raw material. We source:

- Virgin M.S. CRC scrap from auto ancillary units in NCR

- High-quality old worn out manganese castings spares for secondary scrap

Alloys

High-quality alloying materials including:

- Ferro Manganese

- Silico Manganese

- Ferro Chrome

Consumables

Essential process materials including:

- Quartz sand

- Olivine sand

- Chromite sand

- Zircon Paint

- Thinner

- Graphite Powder

- Grinding wheels

- Welding Electrodes

- Diesel Oil for D.G. set

- Furnace Oil for heat treatment